2023. 9. 27. 13:38ㆍBusiness

Si, SiC, Quartz

The etching process results in the desired pattern by removing the lower film after the photo process. Etching processes are becoming increasingly important because they directly affect semiconductor yields.

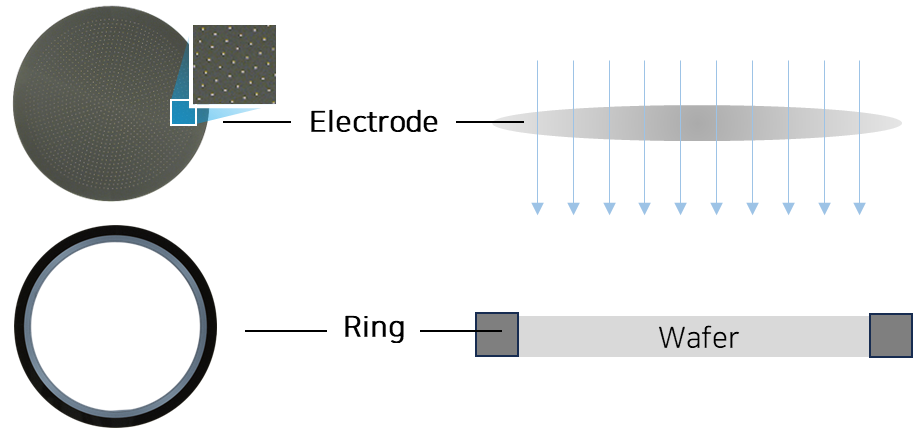

Saehan Nanotech machines are used to produce consumable parts, such as Electrode, Focus Ring, etc., which are components used for the semiconductor etching process.

First, the Ingot Muti Wire Sawing Machine cuts the ingot into 5~6 pieces. It uses a diamond wire saw so that the roughness of the sawing sides is very clean and enables it to work easily in the next process. Single Wire Sawing Machine also uses a diamond wire saw and it is specialized in cutting for thick products.

For Ring(semiconductor etching process consumable parts), we need a core drilling process that removes the core part of the ingot so that we can achieve the tube shape of the ingot.

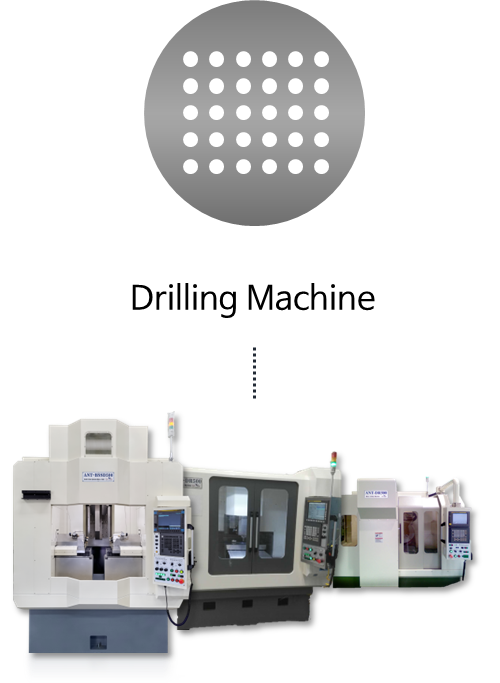

For Electrode (semiconductor etching process consumable parts), we don't need a core drilling process so move to the multi-wire sawing process directly. After the sawing process, a drilling process is required. The drilling process creates micro holes in the electrode, and the etching process causes plasma gas to pass between those holes.

After going through several processes such as grinding and polishing, the final product is completed.

As the importance of the etching process continues to increase, the precision of consumable parts also becomes very important. Saehan Nanotech has been developing specialized equipment for processing relevant parts for a long time. Customers who wish to produce semiconductor etching process parts should contact our company.

Contact

E-mail: info@saehannanotech.com

Tel: +82-70-7791-7052 / +82-55-586-1331

'Business' 카테고리의 다른 글

| Rare-Earth Magnet Cutting — Precision Diamond Wire Sawing by Saehan Nanotech (0) | 2025.10.24 |

|---|---|

| Business (0) | 2023.01.25 |