2025. 10. 24. 16:58ㆍBusiness

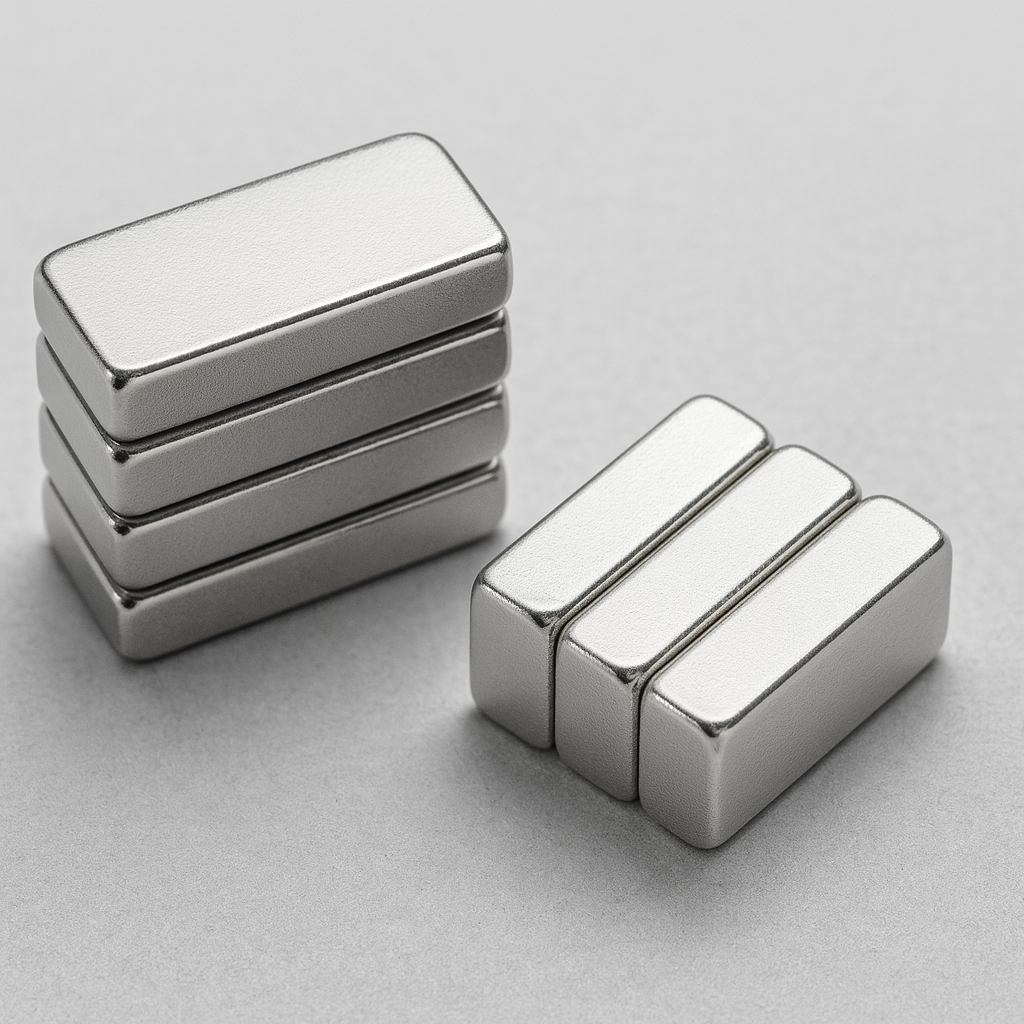

🧲 Rare-Earth Magnet Cutting

Precision Diamond Wire Sawing by Saehan Nanotech

Cutting rare-earth materials such as Neodymium (NdFeB) magnets requires advanced technology that combines precision, safety, and efficiency. Due to their brittle nature and hardness, these materials cannot be processed with conventional sawing methods.

That’s why Diamond Wire Sawing (DWS) has become the standard technique for rare-earth magnet machining.

🔹 Diamond Wire Sawing (DWS) Technology

DWS uses diamond-coated wire(sometimes uses diamond slurry) as the cutting medium, allowing precise and clean cuts even on extremely hard materials. During cutting, a coolant (usually water-based) is essential to control temperature and prevent flammable dust from igniting. This combination of abrasive diamond wire and coolant-based heat management enables stable, high-precision machining without damaging the material surface.

🔹 Saehan Nanotech’s Approach to Rare-Earth Sawing

At Saehan Nanotech, we have developed and refined specialized multi-wire sawing machines designed specifically for rare-earth magnet processing.

Our systems feature:

- Multi-Wire Saw Machines capable of cutting multiple pieces simultaneously

- Precision control algorithms to stabilize wire tension and feed rate

- Customizable configurations for both straight and arc-shaped cuts

- Enhanced coolant flow and filtration systems for safe and clean operation

These features ensure uniform cutting surfaces, minimal material loss (low kerf width), and high repeatability — essential for mass production and R&D applications alike.

🔹 Proven Performance

Since the early 2000s, Saehan Nanotech has independently developed wire sawing and core drilling machines for hard and brittle materials. Our equipment has been successfully used for processing rare-earth magnets and exported to overseas clients who require precise, safe, and efficient machining solutions. In 2024, we also completed Korea’s first motor magnet cutting project, proving the reliability and scalability of our technology.

🔹 Applications

Saehan Nanotech’s Diamond Wire Sawing solutions are applied across multiple advanced industries, including:

- Semiconductor components

- Display materials

- Electric motor and generator magnets

- Optical glass and ceramic substrates

Our precision cutting systems allow complex geometries and tight dimensional tolerances that traditional sawing technologies cannot achieve.

🔹 Moving Forward

As demand for rare-earth materials continues to rise with the growth of the EV and renewable energy industries,

Saehan Nanotech remains committed to advancing diamond wire sawing technology and localized manufacturing.

Through continuous innovation, we aim to lead the global rare-earth machining market with reliable, high-precision, and eco-conscious solutions.

📩 Contact Us

For inquiries regarding rare-earth sawing or magnet machining equipment:

📧 info@saehannanotech.com

'Business' 카테고리의 다른 글

| Rare Earth(NdFeB) Magnet Processing (0) | 2026.02.21 |

|---|---|

| Semiconductor Etching Process Consumable Parts (0) | 2023.09.27 |

| Business (0) | 2023.01.25 |